LOTO implementation process

LOTO Audit

We offer complete Lockout/Tagout (or LOTO) safety procedure implementation services. The entire LOTO safety procedure implementation process includes 4 phases, which we will guide you through completely.

We offer complete Lockout/Tagout (or LOTO) safety procedure implementation services. The entire LOTO safety procedure implementation process includes 4 phases, which we will guide you through completely.

Are you considering introducing the LOTO process into your operation?

The subject of the pre-audit for the introduction of the LOTO procedure is the risk analysis and the actual audit of the facility. The aim is to assess the baseline OSH situation and to propose an optimal solution using LOTO components. The output of the analysis is a brief audit report, a list of recommended LOTO components (including their quantity), a specific price quotation (including training) for turnkey implementation and a schedule of work.

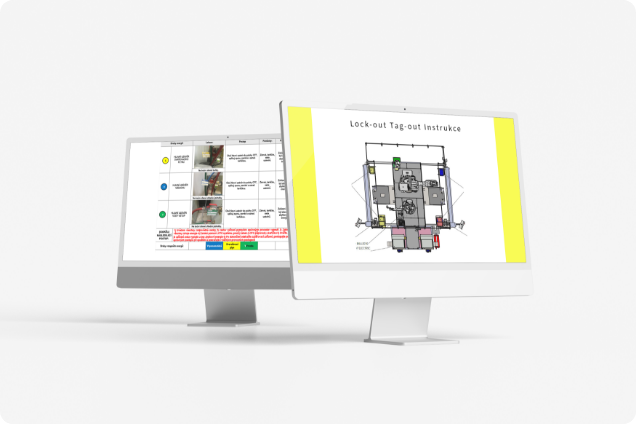

For the purpose of implementing the procedure, it is necessary to physically map all isolation points, create a list of isolation points and a list of devices (instructions), and evaluate the ideal options for locking the respective isolation point in a combination of locks and LOTO elements.

The next step after data collection and analysis within the implementation is to mark all the so-called isolation points. For this process, PVC/metal tags are used to identify where the isolation point is locked. The isolation point disconnection is photographically documented and then imported into the corresponding LOTO instruction.

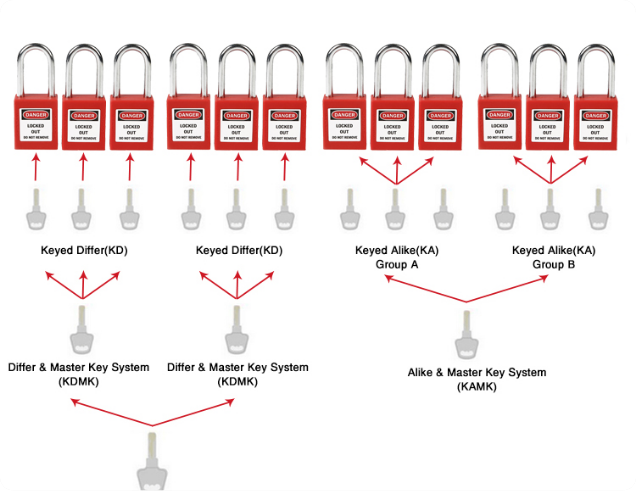

In the area of LOTO implementation, we also provide the design of the so-called keying system. This is a tailor-made keying system in connection with the company’s internal regulations. The system distinguishes between categories of maintenance employees.

The LOTO instruction step results in written instructions for securing the equipment (accompanied by photographs) to secure the risk of the equipment.

Are you thinking about introducing the LOTO process into your operation?

This is a key document that addresses procedures, the use of LOTO equipment, employee rights, etc. with respect to the specifics of individual operations. In addition, the directive addresses the use of locks including keying and other procedures in the daily use of the procedure. The interaction of middle management, maintenance managers and the person responsible for occupational safety is needed in the development of the directive.

Implementing the Lockout/Tagout process cannot be done without proper training of employees and management. The final step in the implementation of the procedure is therefore training, which takes place directly at the workplace.

Contact me and we’ll set up a meeting.

+421 902 189 277 office@aledo.tech

International Sales Manager