Security of dangerous energies

Lockout / Tagout – LOTO

Lockout/Tagout is a safety procedure for securing dangerous machinery and equipment by properly shutting it down and preventing it from being restarted until maintenance or repair is completed.

Lockout/Tagout is a safety procedure for securing dangerous machinery and equipment by properly shutting it down and preventing it from being restarted until maintenance or repair is completed.

Our team of professionals is able to ensure a smooth implementation of this system from the initial audit to the delivery and installation of the final solution.

We are partners of the most important manufacturers of LOTO components – Brady and Masterlock.

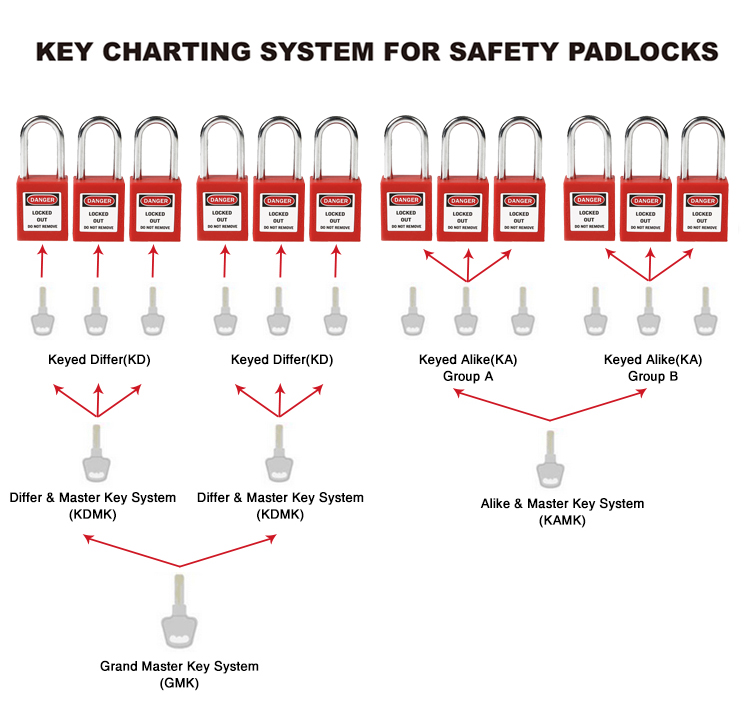

Placing a special lock and padlock in a place that is critical for releasing the power source, in such a way that it is impossible for other persons to turn on the disconnected or shut down machine without using a force.

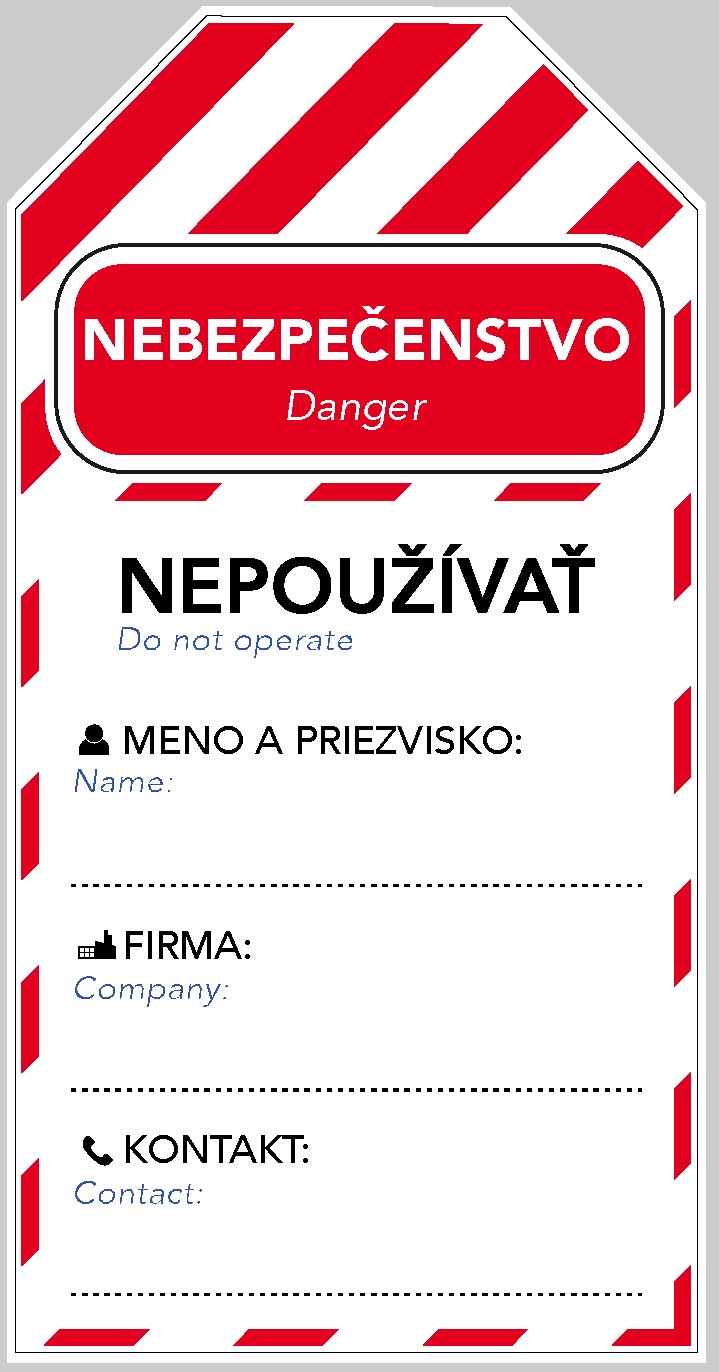

Marking the cap with a tag that informs other users that the device is undergoing repair/downtime and that the device is therefore disconnected/switched off. Information related to the disconnection (name of the responsible worker, date of completion, etc.) can also be written on this tag. A short text can be placed on the back of the tag with a description of the steps the employee must take before turning off or disconnecting the device – with his signature. By doing so, he confirms that he has performed the given steps.

The LOTO system, that means the entire Lockout/Tagout system helps to eliminate safety risks in various types of operations. The main groups of risks that the LOTO procedure successfully eliminates include:

Mechanical risks – prevents the movement of the device or the operation of the machine.

Electrical hazards – limits the risk of electric shock.

Chemical risks – prevents the occurrence of chemicals, dangerous liquids or gas.

In the field of health and safety, our company has been actively participating in the application of LOCKOUT/TAGOUT (LOTO) processes in many companies and in a wide range of business activities for a long time.

Contact me and I will be happy to advise you.

+421 910 463 685 aledo@aledo.sk

CEO